OSHA 1910.28

Important things to know

This section is the first of three new sections in subpart D that consolidate requirements relative to fall protection and falling object protection. The others are 1910.29 Fall Protection Systems and Falling Object Protection Criteria and Practices and 1910.30 Training Requirements.

1910.28(a)(1) – the ruling requires employers to provide protection to workers exposed to falls or falling object hazards.

1910.28(b) – eliminates the prior mandateto use guardrails as a primary fall protection method, allowing employers to choose from one or more accepted fall protection systems, they believe work best in each situation their employees may be exposed to, such as:

-

Guardrail Systems

-

Safety Net Systems

-

Personal Fall Protection Systems

-

Personal Fall Arrest Systems

-

Travel Restraint Systems

-

Ladder Safety Systems

-

Hand Rails

-

Designated Areas

1910.28(b)(1) – the rule requires employers to protect their workers from fall hazards along unprotected sides or edges, that are 4-feet or greater above a lower level. Requirements are also set for fall protection in specific situations, such as hoist areas, runways, areas above dangerous equipment, stairways, repair pits, wall openings, or scaffolds.

OSHA defines fall protection as – “any equipment, device, or system that prevents a worker from falling from an elevation or mitigates the effect of such a fall.” Under the final rule, employers may choose from the following fall protection options:

-

Guardrail System – A barrier erected along an unprotected or exposed side, edge, or another area of a walking-working surface to prevent workers from falling to a lower level.

-

Safety Net System – Is a horizontal or semi-horizontal, cantilever-style barrier, which uses a netting system to stop falling workers, before they make contact with a lower level or obstruction.

-

Personal Fall Arrest System (PFAS) – A system that arrests/stops a fall before the worker contacts a lower level. Consists of a body harness, anchorage, and connector, and may include a lanyard, deceleration device, lifeline, or a suitable combination. Similar to OSHA’s construction standards, the final rule prohibits the use of body belts as part of a personal fall arrest system.

-

Travel Restraint System – A combination of an anchorage, anchorage connector, lanyard (or other means of connection), and body support, to eliminate the possibility of a worker going over the unprotected edge or side, of a walking-working surface.

-

Ladder Safety System – A system attached to a fixed ladder designed to eliminate or reduce, the possibility of a worker falling off the ladder. A ladder safety system usually consists of a carrier, safety sleeve, lanyard, connectors, and body harness. Cages and wells are not considered ladder safety systems.

HOLES:

1910.28(b)(3) – the ruling requires employers to protect workers from falling into or through any hole, including skylights, stairway holes, ladderway floor holes, hatchway and chute-floor holes, and other holes on roofs. A “hole” is defined as an open space or gap in the floor, roof, or a horizontal walking-working surface, that is at least 12-inches in its smallest dimension.

The hazard can be addressed with a:

-

Cover over the hole

-

Guardrail system around the hole

-

Travel restraint system, or

-

Personal fall arrest system

Openings pose similar hazards and may be addressed by the above (except a cover), and additionally by the use of a safety net system. 1910.28(b)(7)

RUNWAYS and SIMILAR WALKWAYS:

1910.28(b)(5) – employers must protect workers on runways or similar walkways, from falling four or more feet to a lower level, by a guardrail. Employers are no longer required to have toeboards on both sides of runways.

-

If not feasible to have a guardrail on both sides of special purpose runways, the employer may omit guardrail on one side, provided the runway is at least 18-inches wide, and the worker uses a personal fall arrest or travel system.

FIXED LADDERS (that extend more than 24 feet above a lower level):

1910.28(b)(9) – requires employers to provide fall protection to fixed ladders more than 24-feet above a lower level. This also applies to existing ladder systems, if sections are repaired or replaced.

-

For new ladders greater than 24-feet, effective November 19, 2018, they require a personal fall arrest system, or a ladder safety system- such as a parallel cable/rail running alongside, with provisions for tie-off and arrest in the event of a slip or fall.

-

And by November 19, 2018, for existing ladders greater than 24-feet, employers must install a cage, well, ladder safety system, or personal fall arrest system, on fixed ladders that did not have any fall protection.

-

Finally, existing ladders extending more than 24-feet must have either a ladder safety system or personal fall arrest system by 2036.

-

In a new provision, OSHA added a rule that allows employers to use cages and wells in combination with personal fall arrest or ladder safety systems, provided there is no interference.

STAIRWAYS:

1910.28(b)(11) – requires employers to protect workers from falling off stairway landings and exposed sides of stairways.

-

Unprotected sides or edges of a stairway landing four feet or more above a lower level, must be protected by a guardrail or stair rail system. Flights of stairs having at least three treads and four risers, must also be equipped with railing and handrails.

-

When floor space is limited, requiring the use of the much steeper ship stairs or alternating tread-type stairs (50 to 70 degrees from the horizontal),OSHA also requires these be equipped with handrails on both sides.

WORK on LOW SLOPE ROOFS:

1910.28(b)(13) – a new position by OSHA, establishes fall protection requirements when workers perform work on low slope roofs (refer back to page 4 for definition). The type of protection required depends on the distance working from the roof edge.The final rule breaks low slope roof work into three zones.

-

If less than 6-feet from the edge: acceptable forms of fall protection are guardrails, safety net systems, travel restraint or Personal Fall Arrest Systems (PFAS).

-

6-feet to less than 15-feet from the edge: acceptable forms are guardrails, netting, travel restraint, or PFAS. An employer may use a designated area (warning line) when performing work that is both infrequent and temporary.

: An employer is not required to provide any fall protection if work is both infrequent AND temporary (refer back to page 4 for definitions), and they implement and enforce a work rule prohibiting an employee from going within 15- feet of edge, without using fall protection.

15-feet or more from the edge – acceptable forms of fall protection are guardrails, netting, travel restraint or PFAS, or a designated area (warning line).

Important things to know, review more articles OSHAs

OSHA’s – 1910.22 General Requirements

OSHA Recognized 3-Levels of Skill- Work at Height

Important Definitions per OSHA

OSHA’s – 1910.140 Personal Fall Protection Systems

OSHA’s – 1910.29 Fall Protection Systems & Falling Object Protection- Criteria and Practices

OSHA’s – 1910.28 Duty to have Fall Protection & Protection from Falling Objects

An Employer’s Duty to Provide Protection from Falling Objects

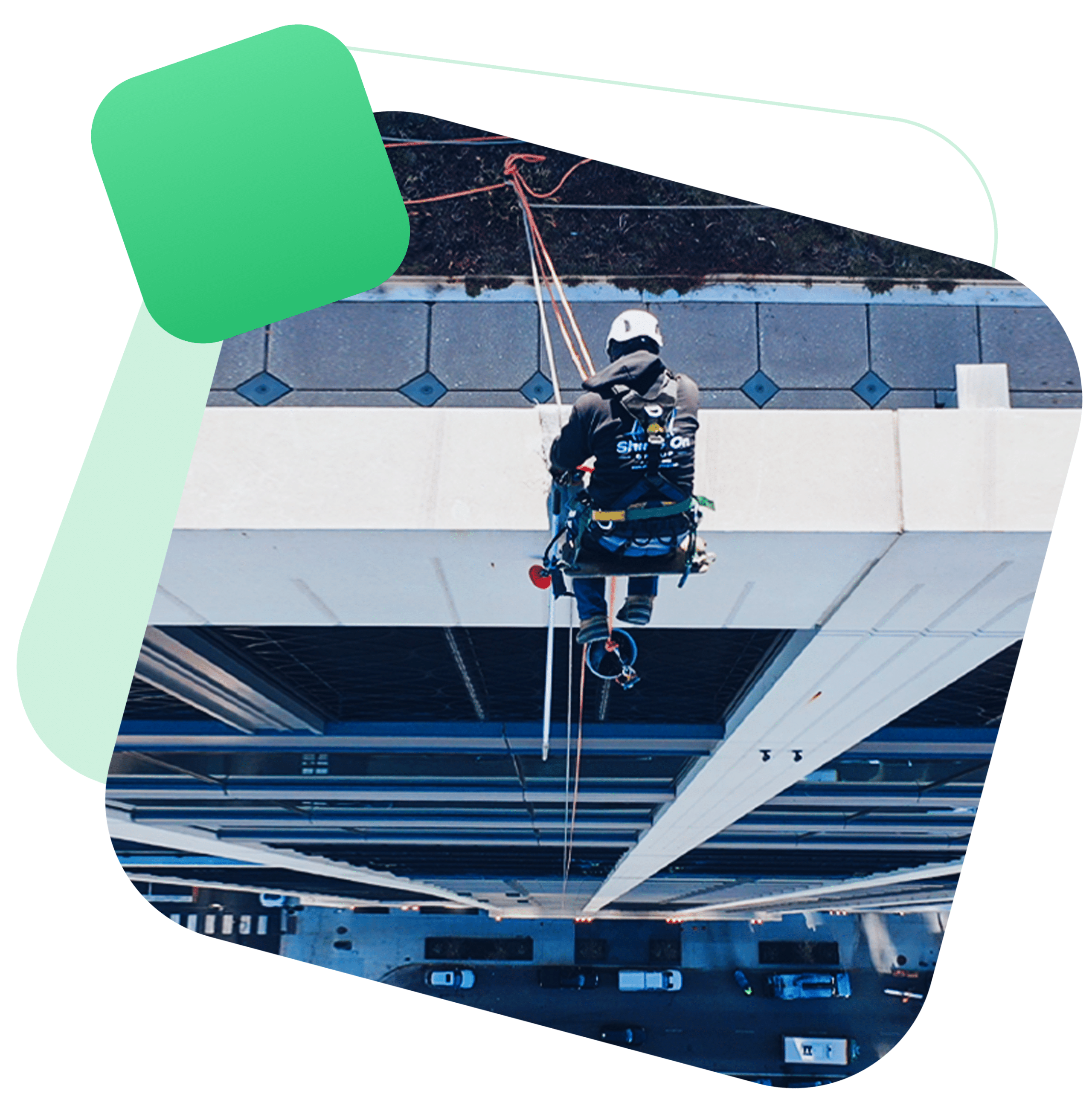

Most people understand that working at height can be a dangerous business. This is borne out by statistics which show that over 800 workers are killed in America each year as a result of falls.

Every employer has a moral responsibility to protect their workers from harm. This is backed up by legal requirements that specify what needs to be done in certain situations to prevent falls, particularly the OSHA 1910.28 regulation.

Workers who do fall may kill or injure not only themselves but potentially also anyone who is present below them. This also applies to any objects, such as materials or pieces of equipment being used for the work, that fall from a platform onto the area below. It’s vital to ensure this does not happen in order to protect workers from harm and to avoid financial penalties, compensation claims, and disruption to production that will harm the company.

How the 1910.28 OSHA Regulation Protects Workers

The first step in protecting workers from fall hazards is to identify those hazards. Once you do that, you can put in place the type of protection that is most appropriate for those hazards and the OSHA 1910.28 regulation sets out what these are.

This regulation deals with different types of hazards and situations. The common theme for most of them is that some form of protection must be provided where workers are four feet or more above a surface onto which they can fall.

This section of OSHA regulations does not apply to portable ladders, powered platforms, aerial lifts, or various types of work (such as telecommunications and electric power generation, transmission, and distribution) covered by other sections. Nor does it cover inspections, investigations, and assessments.

OSHA 1910.28 B9 deals with the responsibility that employers have for providing protection from falls and falling objects on work areas and walking surfaces. Protection must be provided:

- where there are unprotected edges and sides

- in hoist areas

- if there are holes, such as skylights, that workers can fall through

- on dockboards

- for runways and walkways

- above dangerous equipment, where protection is needed irrespective of the height

- near openings

- for open pits

- when working on sloping roofs.

In general, for these types of hazards, guardrails, safety net systems or personal fall protection, fall arrest or travel arrest systems have to be provided. These are sometimes not mandatory if it can be proved that they are not feasible, although a fall protection plan must be implemented instead. Provisions are also provided for the use of fixed ladders, stairways, scaffolding and rope descent systems, where different regulations apply.

Why Professional Installation is Essential

The whole process of what is needed and where is very complex, and failures to comply can have serious consequences. The best, and possibly only, way to comply is to use a professional organization that is experienced and knowledgeable in the need for and use of safety equipment.

At Shine On Anchors, we have many years of experience in supplying and installing all types of safety systems. We know what is needed and how best to install and use it. We design and fabricate each system to meet individual needs and can ensure you are always fully compliant, and your workers are kept safe. So contact us and have no further worries about doing things the right way.